A Cleaner, Sustainable Future for Swanbank

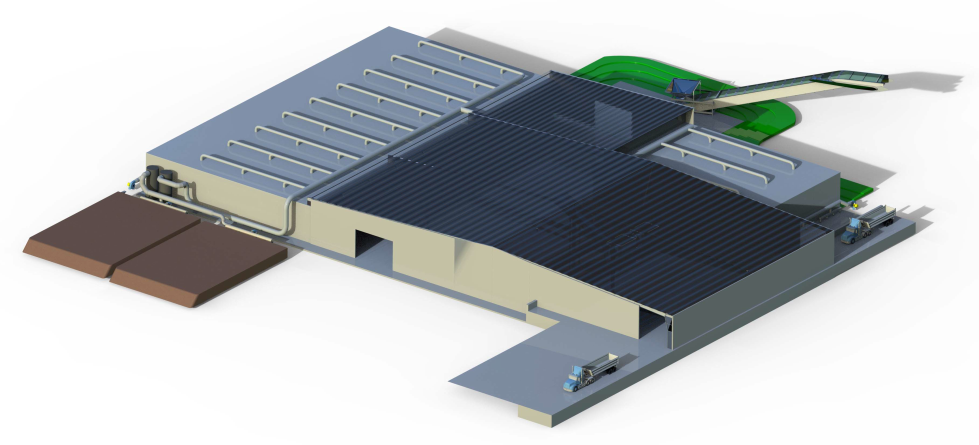

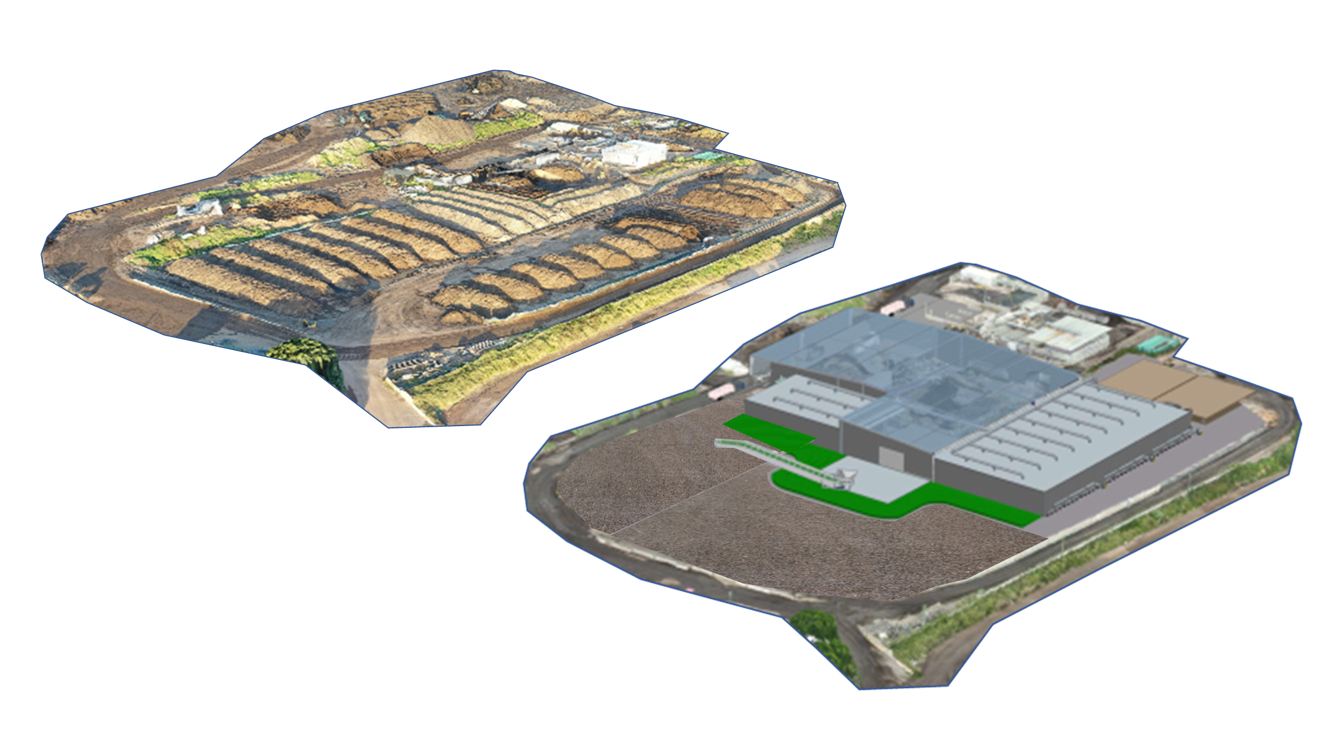

We’re upgrading our Ipswich facility with a new In-Vessel and Enclosed System (IVES) to strengthen our composting process, reduce odours, and better serve our community, clients and environment.

What is Changing at the Site

We’re transitioning from our temporary Mobile Aerated Floor (MAF) to an IVES to improve our composting process. The site upgrades will be broken down into two distinct stages however, the entire IVES will be implemented within the shorter of 21 months of receiving development approvals from Ipswich City Council or within four years of the Court Order Date being September 18, 2028.

This modern In-Vessel and Enclosed composting technology will help us to meet both regulatory standards set by the Department of the Environment, Tourism, Science and Innovation (DETSI) and Ipswich City Council (ICC), while also responding to community expectations.

Upon completion, the upgraded Ipswich facility will be the largest and most advanced IVES composting facility in Queensland.

We have been operating in Swanbank since 2007 as Queensland’s largest compost manufacturer. Following Planning and Environment Court proceedings on 18 September 2024, we are implementing several site and operational improvements.

The New System

The new system will allow us to manage composting within fully enclosed tunnels and sheds, where airflow is controlled, and emissions are extracted through biofilters for treatment, which will significantly improve air quality and reduce off-site odour.

Interim Operational Improvements

These solutions demonstrate that we are taking proactive steps to manage odour while upgraded infrastructure is designed, approved, and constructed. These changes will deliver significant benefits to the local community while maintaining our support of circular economy practices across the region.

- Installation of an enclosed liquid deposition tank which is maintained under negative air pressure to receive and hold odorous liquid waste streams. Odorous emissions from this tank are treated via a biofilter.

- Chemical treatment of incoming odorous wastes to reduce odour.

- Reduced incoming commercial waste volumes and refusal of several highly odorous waste streams to minimise the potential for odour emissions.

- Installation of a MAF System in 2024 to improve airflow through our compost piles to ensure aerobic conditions are maintained resulting in improved odour control.

- Targeted aeration and turning schedules to minimise odour release during the most active stages of composting.

- Additional onsite resources for improved site management and increased environmental monitoring and reporting.

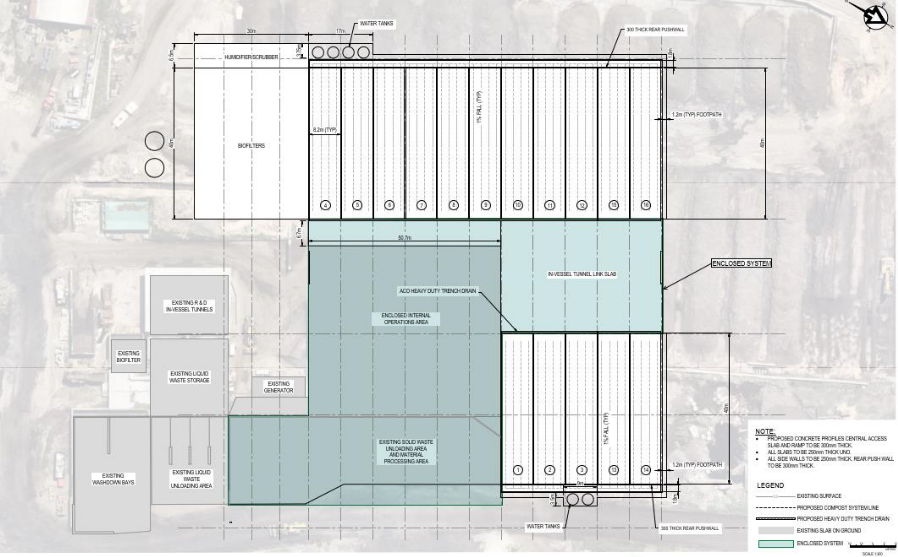

The New IVES Will Include

In-Vessel Tunnels

Sixteen (16) sealed composting tunnels with an integrated aeration system, two (2) biofilters and associated ancillary infrastructure, which will improve odour containment during the most active and odorous composting phase. The bunkers are 8.2 metres wide, 40 metres long and 6.8 metres high. The biofilters are 20 metres wide and 30 metres long.

Enclosed Receival and Mixing System

All odorous materials used as inputs to the composting process will now be received, handled and mixed in sealed, negative-pressure buildings with air treated through biofilters to minimise emissions at the source. After this step, the material is immediately transferred to the in-vessel tunnels to facilitate the composting process.

Facility Location

The site is located at Lot 3 Unnamed Road, Swanbank QLD 4306, formally known as Lot 3 on SP289972 (the subject site) and comprises an area of approximately 21.15 hectares. Vehicle access to the subject site is currently obtained from Memorial Drive via an existing access arrangement located within the north-west corner.

The site sits within the Swanbank / New Chum area, which is characterised by a concentration of industrial activities, including waste processing, high-impact industrial manufacturing, and electricity infrastructure. The area has a history of mining and extractive industries, with several sites having since been repurposed for waste and landfill operations.

What This Means for the Community

Our goal is to build stronger and more transparent relationships with our community through improved technology, open communication, and real-time environmental performance monitoring. This upgrade focuses on enclosing composting processes, treating emissions, and improving incoming odorous materials from the moment it arrives onsite. It also ensures the site meets modern standards for odour control and sustainability.

Reduced Odour

Significant reduction in odour emissions from NuGrow’s facility, helping to reduce the cumulative impact of odours from the Swanbank Industrial Area.

Transparent Reporting

Transparent public reporting and information sharing about our operations and environmental performance.

Sustainable Future

Continued support for a more sustainable future through improved organics recycling practices.

Our Commitments

We’re committed to being a responsible operator and a trusted neighbour. The IVES represents a significant long-term investment in improved outcomes for the environment, the community, and the future of sustainable organics recycling in Queensland.

- Implementation of best-practice odour control technology.

- Regular community updates and provision of project information.

- Meeting environmental conditions enforced by the Court, ICC and DETSI.

- Long-term transparency in reporting and compliance.

- Support sustainable waste management practices in Ipswich and across the Queensland region.

This strategy sets a new benchmark for how organics recycling practices can be implemented, responsibly, transparently, and with the community in mind.

Project timeline

Our site has been earmarked for significant infrastructure upgrades and operational improvements for several years. We are working closely with ICC and DETSI to meet all required milestones.

Stage 1: Interim Measures

Mobile Aerated Floor (MAF) system introduced to improve airflow and odour control for compost piles. This is a temporary solution to reduce odour while permanent systems are designed, approved, and constructed.

Timeline: Completed in 2024 – one month after the Court order.

Stage 2A: Modification-Change Application (Minor Change)

This planning approval application to the current development approval was lodged with the Ipswich City Council on 18 March 2025. This application aims to replace the approved Engineered Membrane System (EMS) by bringing forward the delivery of the In-Vessel System (IVS) earlier than originally anticipated.

Timeline: Submitted 18 March 2025 and approved by ICC on 12 September 2025.

Stage 2B: Modification-Change Application (Other Change)

This planning approval application seeks to facilitate the following changes to site processes and infrastructure including:

Clarification of areas used on the site for finished compost storage, additives storage, blending and screening, having regard to current condition (d), (d)(i) and (d)(ii) and Annexure A of the current development permit.

Implementation of the Enclosed System.

Substitution of the previously approved above ground ring tank for an in-ground, synthetic lined leachate and stormwater containment dam.

- Incoming waste temporary storage and transfer offsite.

Timeline: Submitted 18 March 2025 and currently with ICC for assessment.

Stage 3: In-Vessel System Construction

Sealed negative pressure composting tunnels with an integrated aeration system, biofilters, automated controls and associated ancillary infrastructure.

Timeline: Anticipated to be commissioned and operational by 18 September 2026.

Stage 4: Enclosed waste receival and mixing system construction

Sealed, negative-pressure buildings with automated controls, biofilters and internal air recirculation.

Timeline: Lesser of 21 months from date of order or 18 September 2028.

Contact us

We’re here to work together. For more information, please reach out through our dedicated community email.

Phone

Address

Building 7, Level 1, 22 Magnolia Drive, Brookwater Qld 4300

Contact us

Frequently Asked Questions (FAQs)

1. What Council approvals is NuGrow currently seeking?

We have submitted two town planning applications to our existing Development Approval (Application Number: 7213/2014/MAMCD) with Ipswich City Council. The proposed changes relate to upgrades at our Ipswich facility, which includes:

- Minor Change application – to replace the previously approved temporary Engineered Membrane System (EMS) with a fully enclosed In-Vessel System (IVS) sooner than originally anticipated, and

- Other Change application – to deliver broader site improvements, including an Enclosed System for receival and mixing areas, updating site layout for additives and compost storage, and refining site boundaries.

These upgrades aim to enhance environmental outcomes and reduce odour impacts. In addition to these, supporting approvals such as Operational Works Applications have also been submitted to assist with delivering the upgrades.

2. What regulatory standards is NuGrow required to meet?

Our operations are regulated under both state environmental legislation and local planning requirements. Our Ipswich facility operates under:

- A Development Approval issued by Ipswich City Council (ICC) under the Planning Act 2016, which includes conditions relating to land use, infrastructure upgrades, and ongoing site management. This approval also considers the provisions of Temporary Local Planning Instrument (TLPI) No.1 of 2023 (Resource Recovery and Waste Activity Regulation), which introduces additional planning controls to manage waste-related activities and protect sensitive receiving uses in the Swanbank and New Chum areas.

- An Environmental Authority issued by the Department of the Environment, Tourism, Science and Innovation (DETSI) under the Environmental Protection Act 1994, which regulates how we manage composting, emissions, and Listed Waste.

The approval includes enforceable conditions that cover the following:

- Managing and reducing odour to avoid environmental nuisance, in line with Section 440(2) of the Environmental Protection Act 1994.

- Receiving, handling and processing Listed Waste under strict containment and environmental controls.

- Monitoring potential environmental impacts, including odour leachate, stormwater and groundwater.

- Maintaining operational procedures and records, undertaking environmental reporting, and complying with timelines set by the Planning & Environment Court (P&E Court) for site upgrades.

- Complying with ERA 53 model operating conditions, which provide baseline environmental performance requirements for organic material processing facilities across Queensland.

3. Why is NuGrow undertaking these upgrades?

We are required to implement specific operational and infrastructure changes following consent orders from the Planning & Environment Court (P&E Court). These changes are part of a broader commitment to improving environmental performance and aligning with industry best practice for composting facilities. The upgrades will also ensure our site meets modern standards for odour control and sustainability.

4. Is NuGrow planning to expand its site?

No, this application is not expanding the site’s footprint or processing capacity. The focus is on improving how materials are managed and processed, particularly by enclosing composting operations to better contain odour emissions. These upgrades are designed to enhance environmental performance, not to scale up operations.

5. What is the proposed timing for the site upgrades?

The proposed site improvements align with the directions stipulated in the Planning and Environment Court (P&E Court) proceedings.

Key milestones include:

- Stage 1: Interim odour control – completed

- Stage 2A: Application to Ipswich City Council for approval to construct In-Vessel System – currently awaiting approval

- Stage 2B: Application to Ipswich City Council for approval to construct Enclosed System – currently awaiting approval.

- Stage 3: In-Vessel System construction – anticipated to be commissioned by 18 September 2026.

- Stage 4: Enclosed waste receival and mixing system construction.

We will continue to keep the community informed as each milestone progresses.

6. What is NuGrow doing to reduce odour?

We understand that odour has been a longstanding concern for the local community, and we acknowledge the cumulative impacts from multiple facilities operating in the Swanbank area. We are doing our part to reduce odour and improve local amenities.

In response, several mitigation measures are already underway on site, and we are also planning to deliver a new In-Vessel and Enclosed composting facility. The construction of this system is designed to contain emissions, treat air through biofilters, and minimise the risk of offsite odour.

This improvement reflects our long-term commitment to operating responsibly, meeting regulatory expectations and being a better neighbour to the Ipswich community.

7. What is NuGrow doing to tackle the odour in the meantime?

While we work towards delivering the long-term In-Vessel and Enclosed System, we have already implemented a number of interim odour control measures on-site to help reduce emissions in the short term. These include:

- Enhanced composting methods using a Mobile Aerated Floor (MAF) System to improve airflow and processing efficiency.

- Improved site management practices and monitoring. This includes dedicated handling procedures for high-odour materials, such as Listed Waste, with measures such as quicker processing times, chemical treatment, enclosed transfer where possible, and restricted exposure during unloading and mixing.

- Targeted aeration and turning schedules to minimise odour release during the most active stages of composting.

These measures are introduced to reduce nuisance odour for surrounding residents and demonstrate that we are proactively managing impacts while permanent solutions are designed, approved, and constructed.

8. How will the In-Vessel and Enclosed System help with odour?

In-Vessel and Enclosed System composting is a fully enclosed process, where organic material is wholly contained within an enclosed structure. This setup allows for more precise control of temperature, airflow, and moisture. This means odour issues can be better managed through filtration systems before being released into the environment.

9. What are the benefits of NuGrow’s operations for the Ipswich community?

We contribute to sustainable communities by turning organic waste into high-quality compost instead of this material being sent to landfill and resulting in negative environmental outcomes. By recycling this organic waste NuGrow is reversing the contributors to climate change whilst also creating a product that will support agriculture, landscaping, and land rehabilitation across Queensland. Our operations also involve ongoing investment in infrastructure that meets higher environmental standards, helping deliver cleaner, greener waste solutions for the Ipswich region and across the Queensland region.

10. Will there be an opportunity to make a formal submission to Council on the Minor Change application?

While the current Minor Change application does not involve any formal public notification, Ipswich City Council will consider the submissions made during the earlier development application processes as part of their ongoing assessment.

For the separate Other Change application, a formal public notification period will be undertaken. During that time, community members will have the opportunity to make a formal submission.

Beyond these processes, your feedback through our channels will help us better understand local priorities and continuously improve how we operate. We’ll continue to provide updates and welcome ongoing conversations with the community.

11. How can I ask a question or submit feedback to NuGrow?

12. How does NuGrow respond to community feedback?

We take all feedback seriously. When you contact us, your feedback is reviewed and becomes an integral part of our continuous improvement process. Where required, we report complaints to the Department of the Environment, Tourism, Science and Innovation (DETSI) and use it to guide operational improvements on site. We are committed to responding promptly and respectfully to all enquiries.

13. Which authorities oversee and regulate NuGrow’s operations?

Our activities are regulated by the Queensland Department of Environment, Tourism, Science and Innovation (DETSI) via strict compliance standards outlined by Environmental Authority. Ipswich City Council regulates the land use component of our operation via an Application for a Development Approval and associated conditions / plans.

14. Will there be any significant impact on traffic and the transport network?

No, the proposed changes under both applications relate only to how composting is managed on-site, including infrastructure upgrades and odour control measures. There are no changes to production volumes, vehicle access arrangements, haulage movements, fleet types, or transport routes. Therefore, the upgrades will not impact traffic flow or the surrounding transportation network.

15. Will NuGrow continue to work with Ipswich City Council?

Yes, we remain committed to working closely with Ipswich City Council. While Council has recently entered a new agreement for kerbside garden organic material processing, our facility continues to operate under an approved Development Approval. We will continue to engage with Council through development processes, compliance reporting, and environmental performance monitoring, as we progress the site upgrades, (as outlined in Question 5), to reduce odour and deliver better environmental outcomes for the Ipswich community.

16. What is the Queensland Health public health enquiry, and is NuGrow involved?

In January 2025, Queensland Health launched a formal public health inquiry into potential health impacts associated with odours from industrial activities in the Swanbank and New Chum areas.

While NuGrow is not the sole focus of the inquiry, we acknowledge the cumulative impacts of odour in the region, and will unequivocally support any process that aims to address community concerns. We will continue to cooperate with all relevant regulators, including Queensland Health.

The inquiry is being led by an independent panel and the final report has been provided to the Minister for Health and Ambulance Services on 30th June 2025.

For more information, visit: Swanbank Public Health Inquiry